Home Applications VOC Recovery Organic Solvents

Recovering Organic Solvents from Factory Wastewater

Organic solvents are widely used in various applications such as in paints, cleaning fluids, and inks. However, these substances can easily vaporize into the atmosphere, and if discharged into the environment, they have the potential to negatively affect air quality, water quality, and soil, raising concerns about human health impacts. Consequently, there are regulations in place to control their emission, and businesses are encouraged to reduce their discharge amounts.

Factories, which often use solvents in large quantities, require equipment or systems to separate and recover organic solvents from wastewater. One common method involves the use of activated carbon adsorption. However, this method requires the regeneration of activated carbon (through incineration), and due to the large size of the equipment and high costs, its implementation can be challenging.

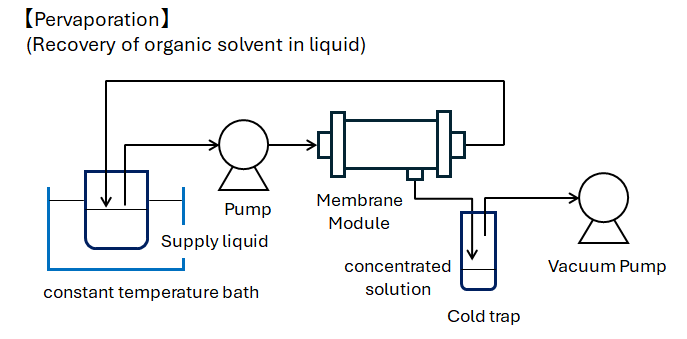

Pervaporation, a membrane separation technique that evaporates liquids through a membrane, is gaining attention as an alternative for the separation and recovery of organic solvents. This method is straightforward and requires less energy. Silicone rubber, known for its chemical resistance and relatively high gas permeability, is considered a suitable membrane material. Its high affinity for organic solvents enables the selective separation and recovery of these compounds from wastewater. For example, it has been used to separate and concentrate methyl ethyl ketone (MEK) from mixtures of MEK and water. This technology holds promise for the recovery of other solvents such as phenols, amines, halogenated solvents, and for concentrating alcohols.