Abstract

“VOC” (volatile organic compounds) is a general term for organic compounds that are volatile and become gases in the atmosphere. It includes various substances such as gasoline, toluene, and chlorofluorocarbons. These substances are known to cause air pollution related to photochemical oxidants and are related to ozone layer depletion and global warming. Emission regulations have been taking shape in Europe and the United States. The emission regulations have been started in Japan on April 1, 2006.

No need to mention the petroleum through vents, most VOCs are contained as solvents in adhesives, paints, inks, etc., they are discharged from chemical product manufacturers and printing-related facilities. Also, electronic parts and metal processing manufacturers use VOCs as cleaning agents.

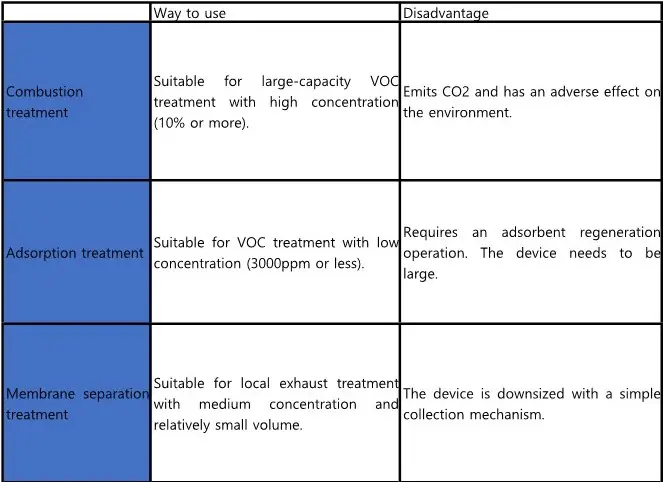

There are two types of VOC emission countermeasures: combustion treatment and separation / recovery treatment. The separation / recovery method includes adsorption by activated carbon and membrane separation operation with selective permeable membrane.

NAGASEP is a separation membrane module made of a single material of silicone rubber and has excellent properties for separating and concentrating VOCs. Membrane separation is a process that takes advantage of specific selective permeability of silicone membrane to the target component.

The device has a simple structure in which a vacuum pump and a steam recovery container are installed besides the membrane module, and VOCs can be continuously concentrated and recovered by depressurizing the permeation side of the membrane at atmospheric pressure on the gas supply side.

NAGASEP is a separation membrane module made of a single material of silicone rubber and has excellent properties for separating and concentrating VOCs. Membrane separation is a process that takes advantage of specific selective permeability of silicone membrane to the target component.

The device has a simple structure in which a vacuum pump and a steam recovery container are installed besides the membrane module, and VOCs can be continuously concentrated and recovered by depressurizing the permeation side of the membrane at atmospheric pressure on the gas supply side.

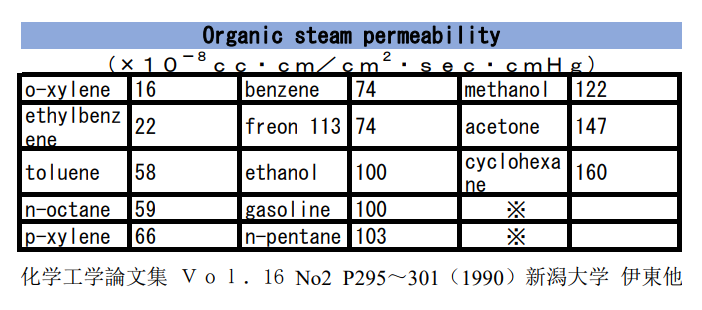

In the picture below you could see the permeability of VOCs in NAGASEP.