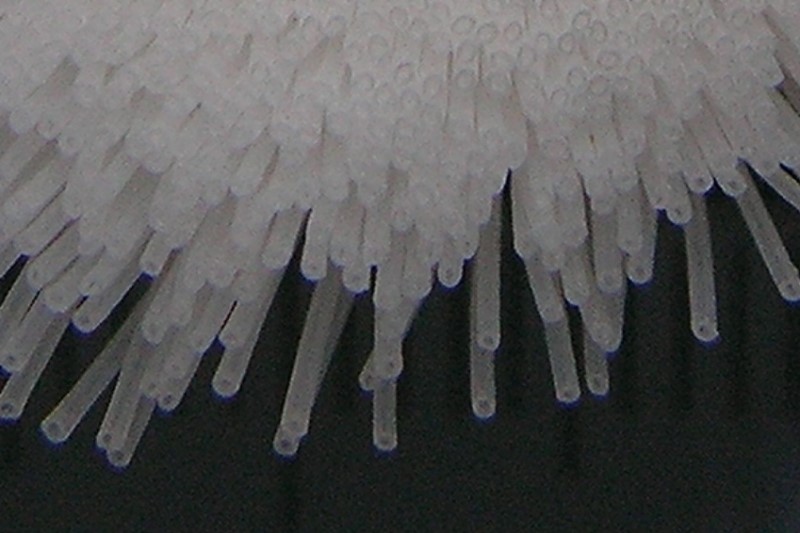

Hollow fiber membranes are thin tubular membranes with a hollow structure inside.They are used in water purifiers for home use, infiltration of alcoholic beverages and drinking water and activated sludge treatment at sewage treatment plants for industrial use, and in hemodialysis machines and artificial lungs for medical use.

The hollow fiber membrane module is characterized by its light weight and large surface area per volume. Therefore, hollow fiber membrane modules are lightweight and can be easily made smaller. Hollow fiber membrane modules consist of a bundle of hollow fiber membranes glued together with resin, and this bundle is contained in a container. The structure is therefore simple and initial costs can be reduced. There are two types of hollow fiber membrane modules: external perfusion type and internal perfusion type. The internal perfusion type performs filtration from the inside to the outside, while the external one does the other way. External perfusion modules have a smaller pressure drop than internal pressure modules and are more energy efficient.

There are two methods for cleaning contaminants from membrane surfaces: physical back-pressure cleaning and chemical cleaning. Most hollow fibre membranes can use either cleaning method. The back-pressure cleaning method applies pressure from the permeate side to wash away contaminants on the membrane surface and can be used in treatment processes that are prone to contamination. When applying chemical cleaning method, the appropriate solvent must be selected according to the application and membrane quality. For example, bacteria and micro-organisms are cleaned with hot water (40-60°C) and sodium hypochlorite, proteins are cleaned with sodium hydroxide and enzymes, fats and oils are cleaned with surfactants and hot water (~80°C), inorganic substances and minerals are cleaned with hydrochloric acid, nitric acid or citric acid.

While most hollow fibre membranes are porous, NAGASEP’s silicone hollow fibre membrane is a homogeneous membrane, which means that it has no pores and will not be clogged with dirt. Therefore, NAGASEP does not require back-pressure cleaning. The membrane surface can be cleaned with various chemicals such as hypochlorous acid, surfactants and acids for contamination of the membrane surface.